Unitedparts’Plastic Injection Integration Services

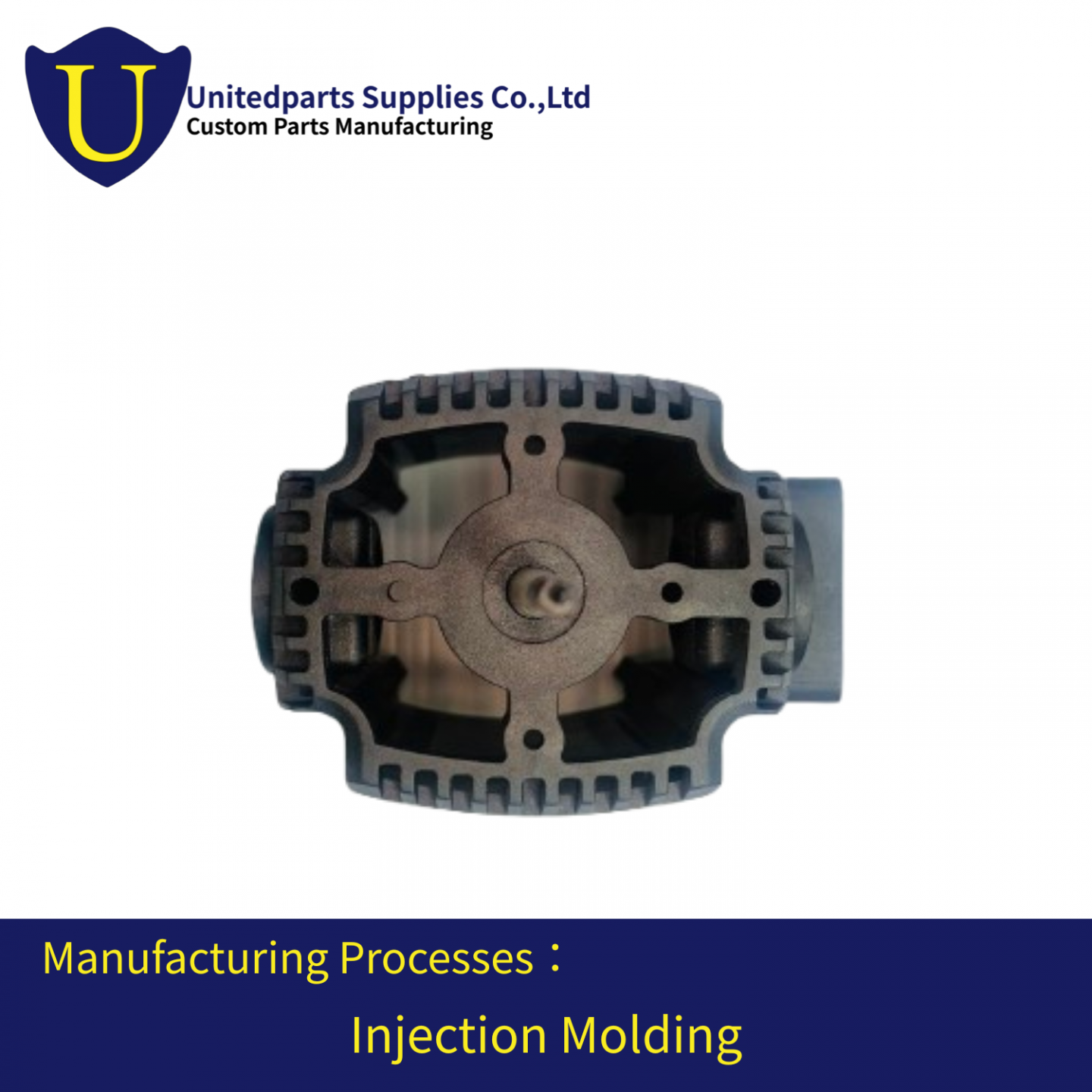

Plastic injection molding is a mature and highly efficient forming technology, with most molded parts ready for direct use after production.

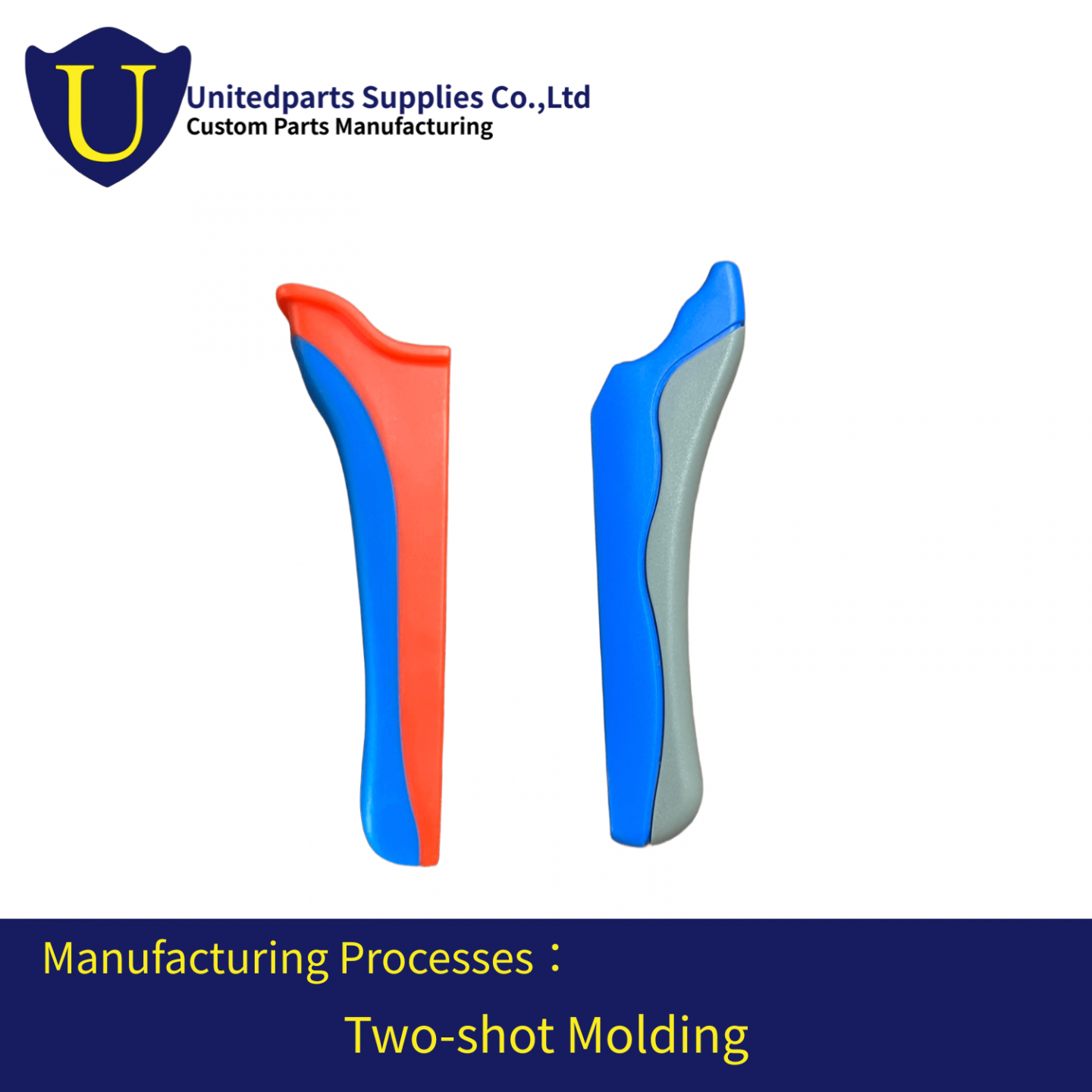

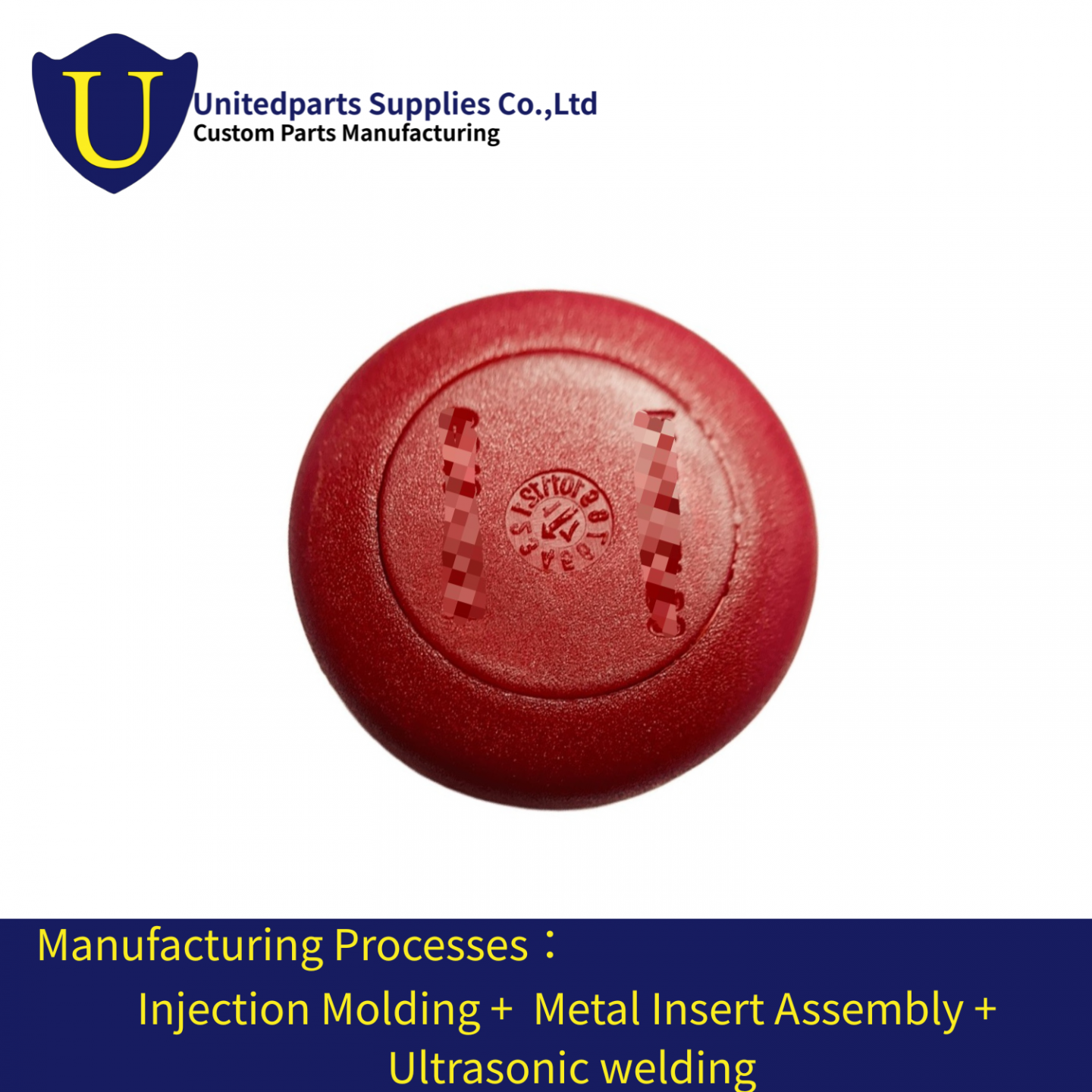

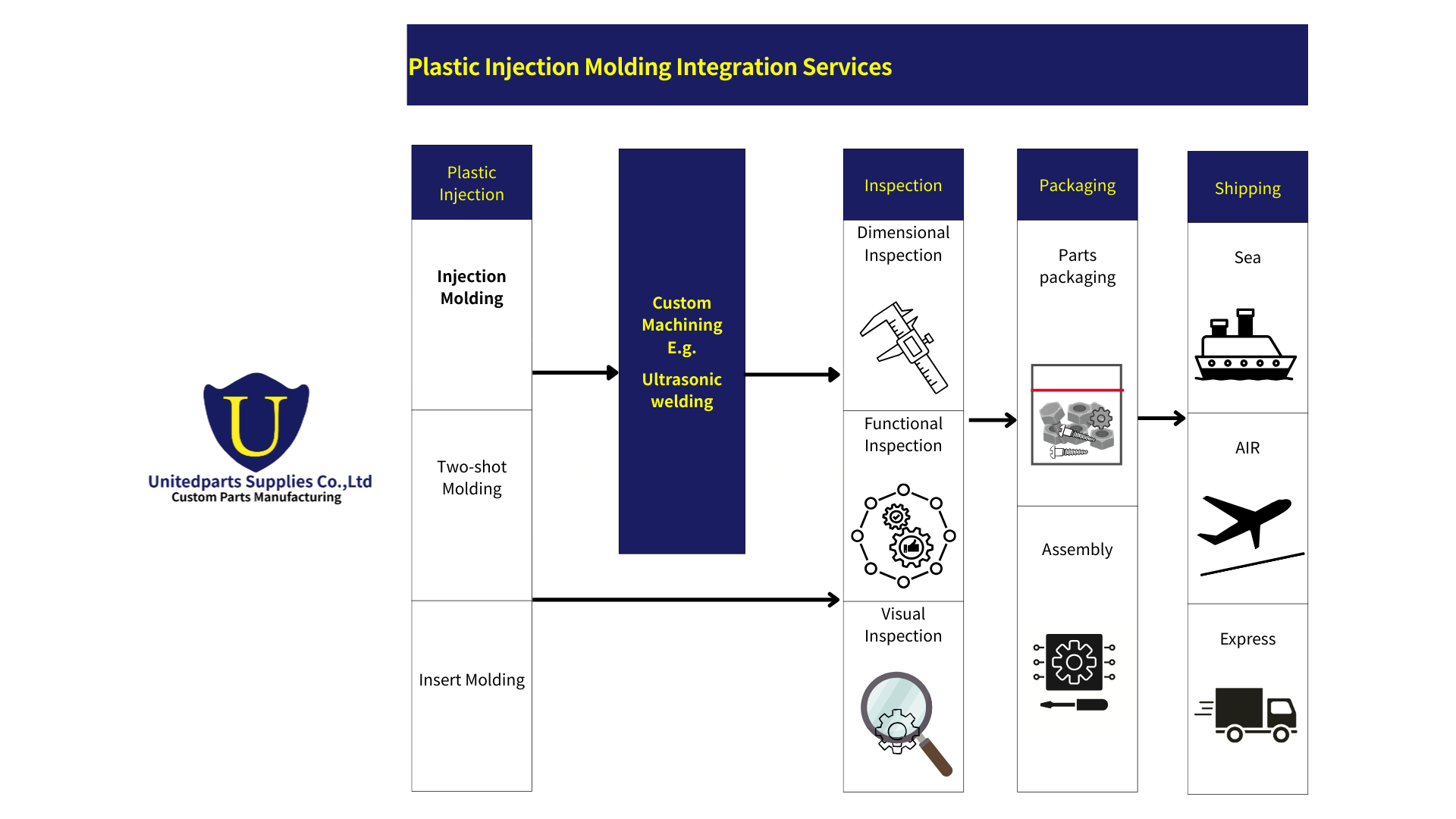

Unitedparts provides comprehensive injection molding integration services, covering single-shot molding, two-shot molding, insert molding, and ultrasonic welding. For insert molding projects, we can also coordinate the required metal components, enabling plastic parts and embedded inserts to be completed in parallel.

Beyond injection mass production, Unitedparts integrates downstream operations such as plastic-to-metal assembly and multi-component packaging.

Unitedparts’Plastic Injection Integration Flow

All stages from molding and assembly to packaging are centrally managed by Unitedparts, forming a complete and coordinated production workflow. This integrated approach ensures consistency in both quality and process control, resulting in stable and reliable product delivery.

Unitedparts’Plastic Injection Integration Scope

|

|

Features | Typical Applications | Materials |

|

Injection Molding |

• Single material injected into the mold and formed in one cycle |

• General housings |

|

|

Two-shot Molding |

• Two different plastics were injected sequentially into the same mold |

• Handles (machine tools, bicycles) |

|

|

Insert Molding |

• Metal or other components placed into the mold prior to injection |

• Electrical connectors |

左右滑動看表格

左右滑動看表格United Processes, Parts with Consistent Quality

Unitedparts plastic injection integration services include injection molding, two-shot, insert molding, and ultrasonic welding, with integrated metal inserts as needed. Post-molding processes such as assembly and packaging are seamlessly coordinated, guiding each part efficiently toward shipment readiness.

With over 20 years of cross-process integration and international project experience, Unitedparts manages molding-to-assembly through a single point of control, ensuring transparency, consistency, and reduced uncertainty.

Contact us to discuss your integrated plastic injection solution.