Unitedparts’ OEM Integrated Services

Unitedparts integrates OEM manufacturing by coordinating multiple suppliers within a structured project framework, matching each process with the most suitable manufacturing capabilities.

The objective is to establish consistent quality and stable production performance across all stages of the project.

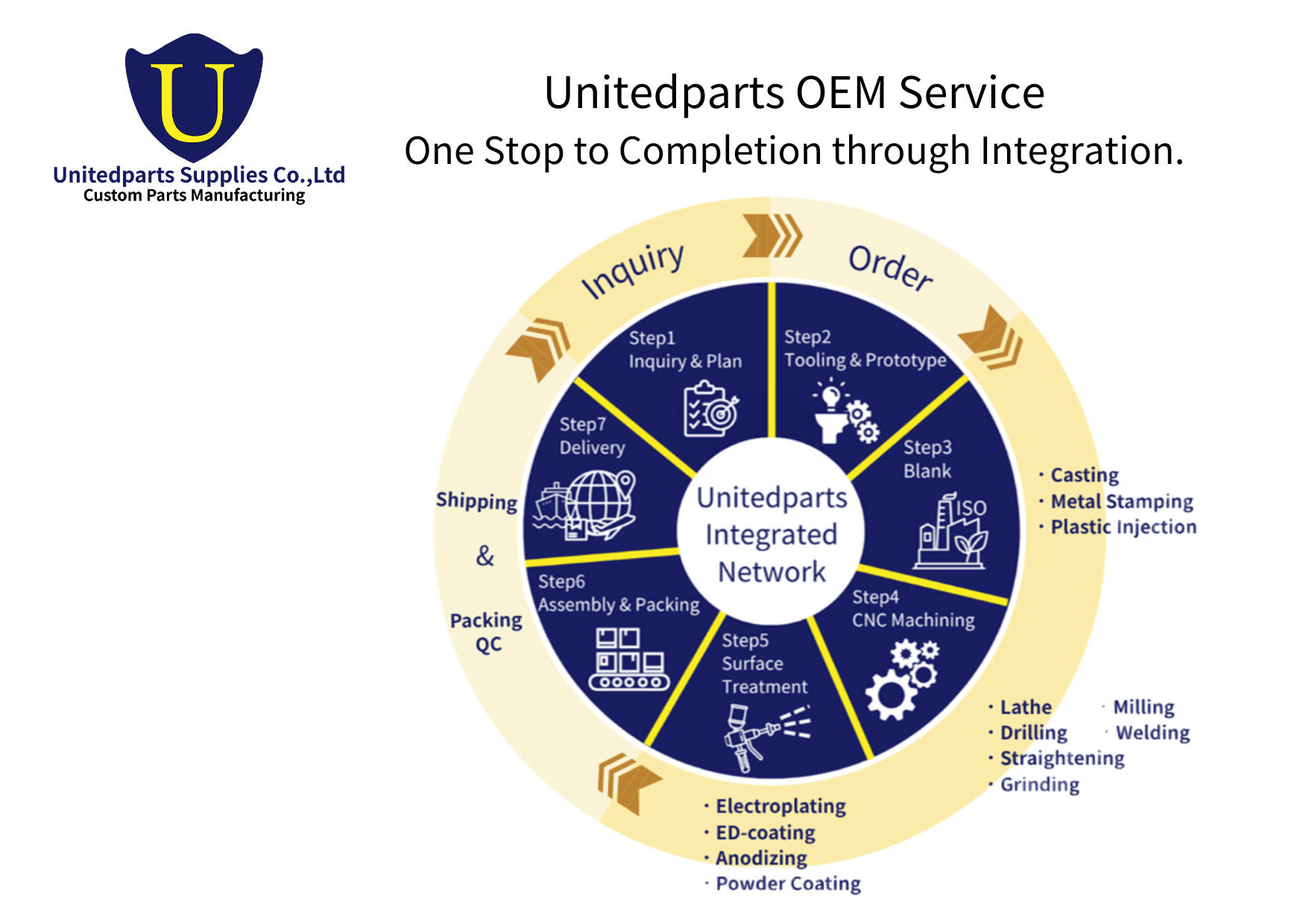

Unitedparts’Integration Scope & Project Flow

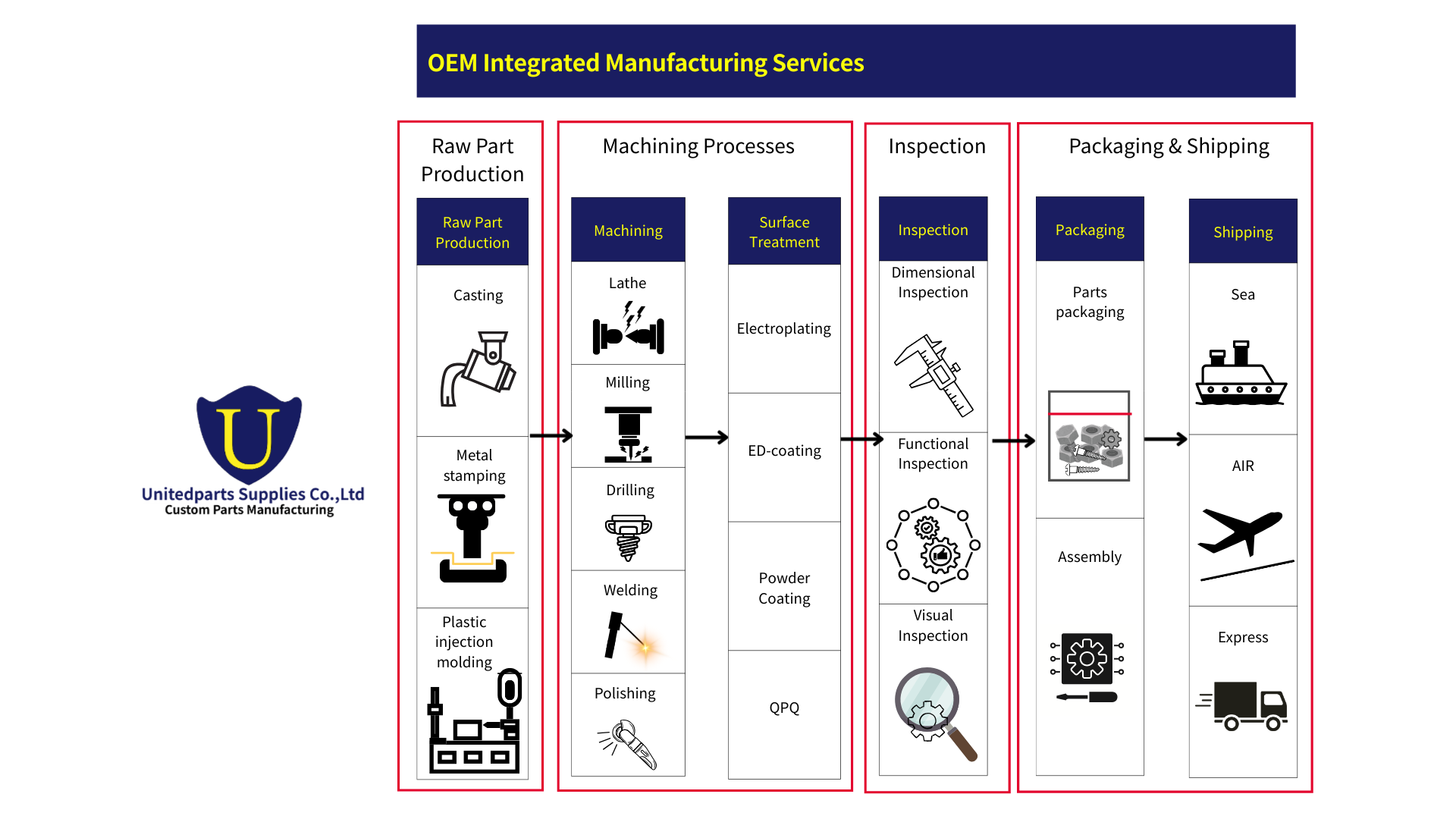

An integrated manufacturing project typically involves raw part production, machining, inspection, and final shipment, taking approximately 90–120 days to complete.

Throughout the project, Unitedparts oversees each critical manufacturing stage to maintain consistent quality across all processes.

The integrated manufacturing scope can be categorized into three main process areas:

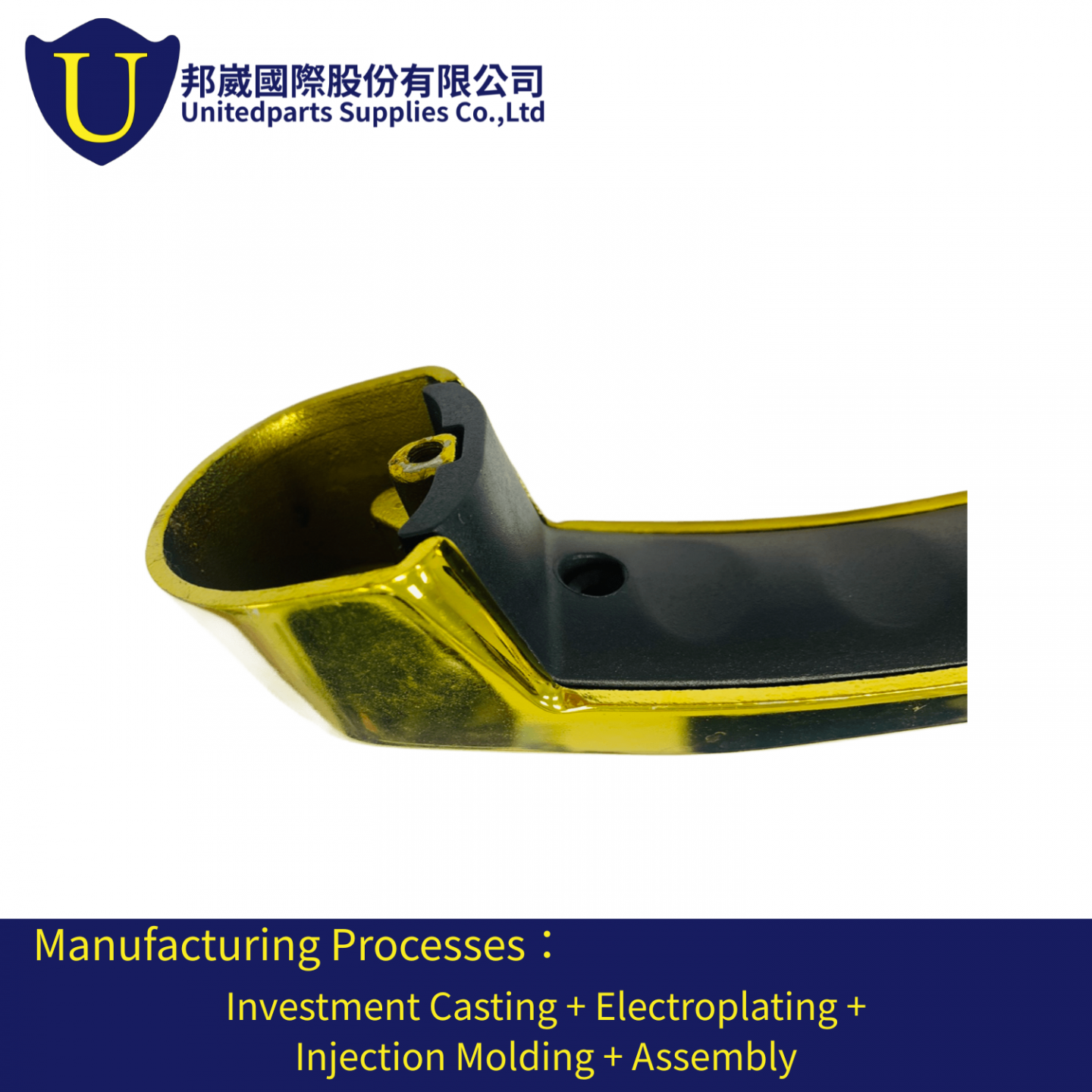

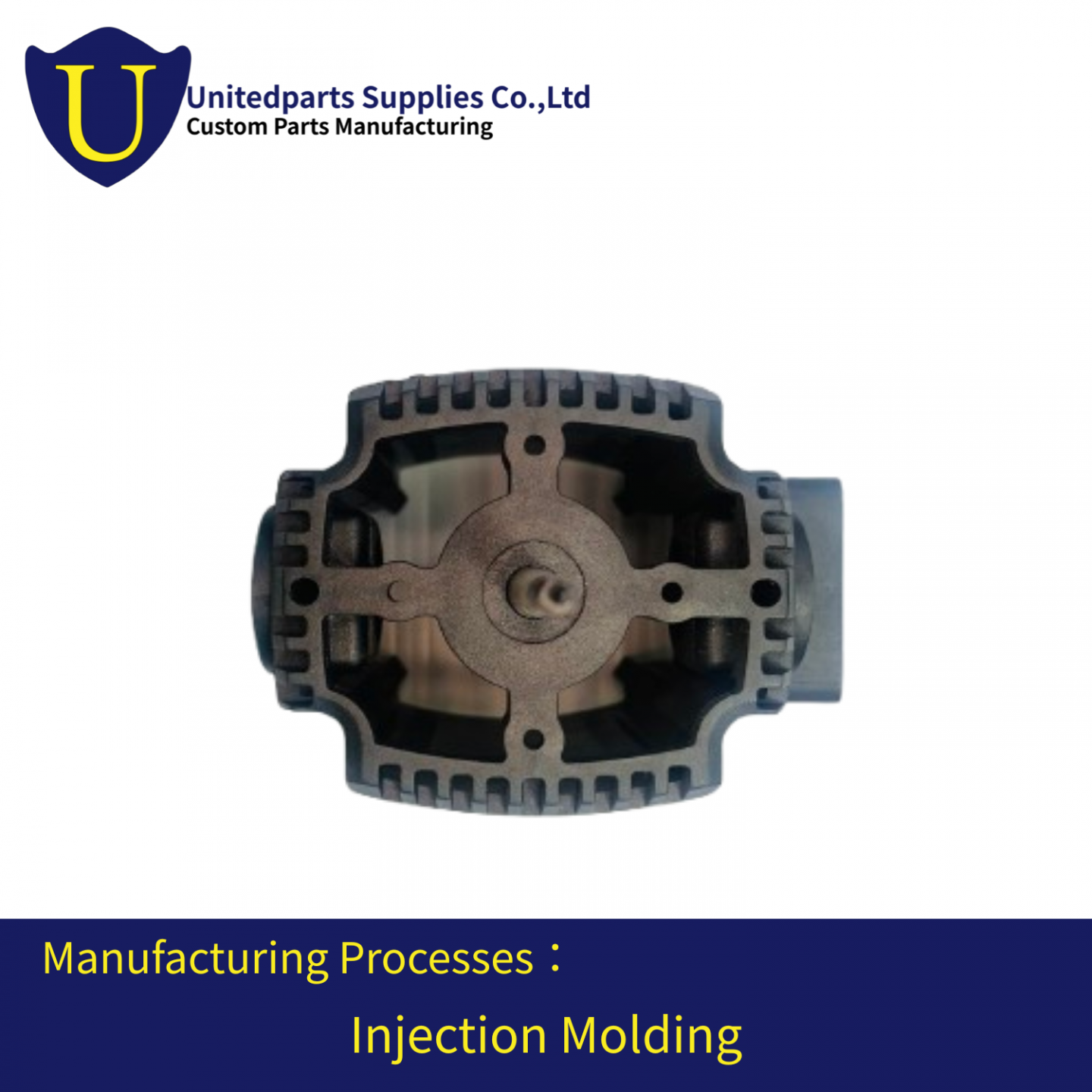

- Raw Part Production: Casting, Metal stamping, Plastic injection molding

- Machining Processes: Turning and milling, Drilling, Welding, Grinding, Electroplating, ED-coating, Powder coating, Anodizing

- Packaging & Shipping: Individual parts packaging, Assembly, Sea and air freight shipment, Express delivery

Unitedparts’Role & Integration Objective

Unitedparts is not a single-process manufacturer, but the coordinator and supervisor of the overall manufacturing flow.

With each process closely interconnected, we implement a structured management and tracking system to ensure consistent quality from raw part production through final shipment.

Our integrated approach is guided by capability alignment and process-specific management, and is structured into six core areas to deliver stable quality that meets defined customer standards.

|

Integration Focus |

How We Do It | Integrated Outcomes |

| Full Process Integration | Production flow charts are defined by process stage. Real-time coordination with partner suppliers is maintained, with on-site verification conducted when required to ensure smooth process handoffs. |

Improved process continuity and information transparency, reducing waiting time and communication gaps. |

| Cross-Supplier Coordination | ISO-certified partner suppliers are selected, with core control personnel directly confirming operational details. Overall shipment defect rates are controlled below 3%. |

Enhanced process consistency and stability, reducing rework and defect rates. |

| Quality Supervision & Inspection | On-site inspections are performed as needed, with inspection reports required for each production batch to verify dimensional compliance with drawings. | A traceable quality system that ensures stable and reliable final product quality. |

| Single Point of Contact | A dedicated project engineer oversees each project end-to-end, ensuring clear communication and accurate execution of requirements. | Project progress and quality can be managed efficiently through a single contact window. |

| Order Consolidation & Shipping | Orders across multiple suppliers or purchase orders are consolidated. Packaging and stacking feasibility is verified before shipment to reduce transport risk and prevent volume waste. |

Supply and internal operations can be planned in advance, improving overall operational efficiency. |

| Issue Handling & Continuous Improvement | Reported issues are reviewed promptly, with corrective actions implemented and historical issues addressed through enhanced pre-shipment inspections. | Continuous quality improvement, ensuring stable and consistent future deliveries. |

左右滑動看表格

左右滑動看表格United Processes, Parts with Consistent Quality

Built on more than 20 years of experience working with overseas customers, Unitedparts supports stable and well-coordinated manufacturing partnerships.

When products involve multiple processes or cross-functional manufacturing, production becomes coordination-intensive, often requiring close follow-up, supervision, and flexible quantity adjustments.

With project management and quality supervision at the core, Unitedparts helps streamline complex manufacturing workflows, reduce communication effort, and ensure each shipment is delivered with stability.

We welcome you to contact us to discuss project details.