Unitedparts’Metal Stamping Integration Services

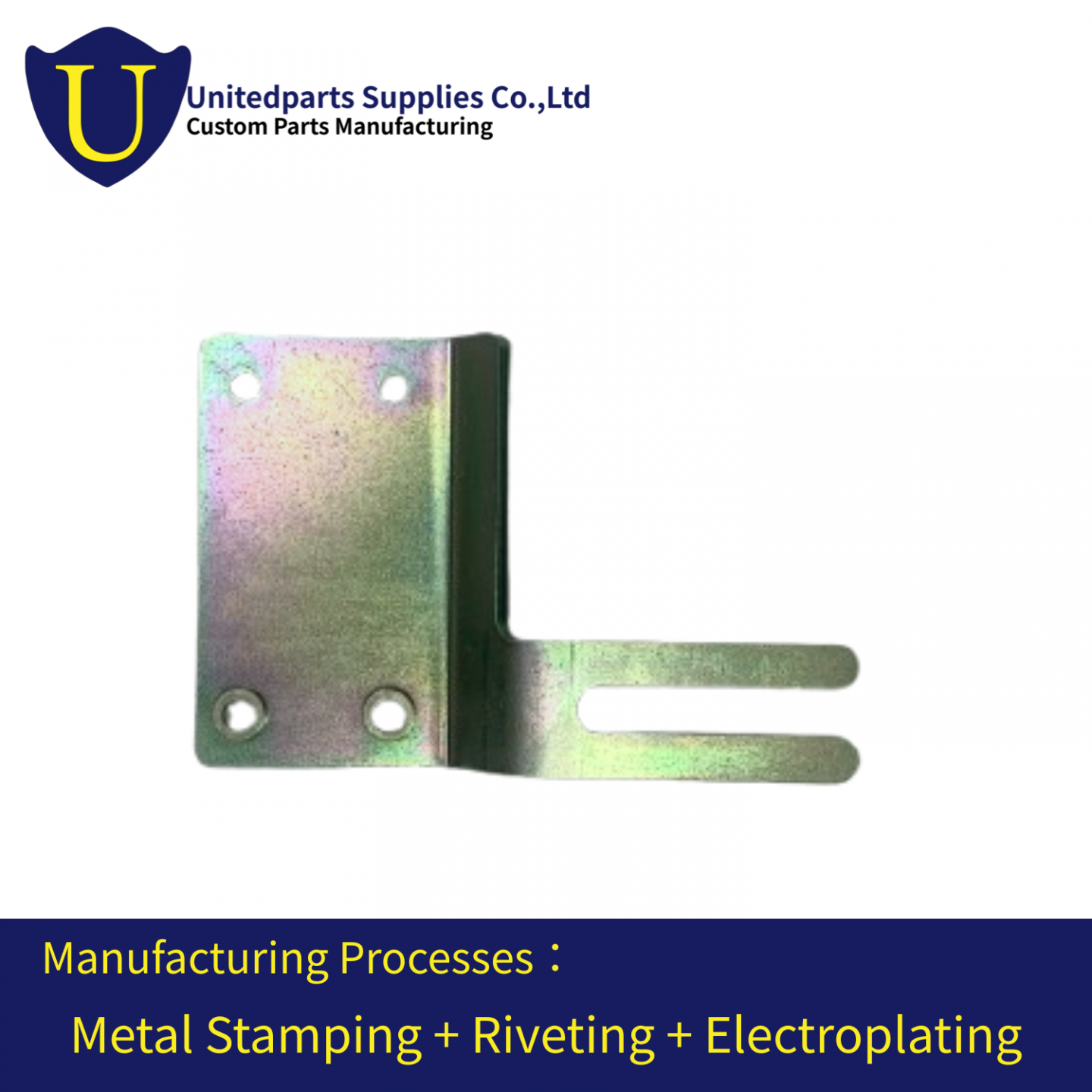

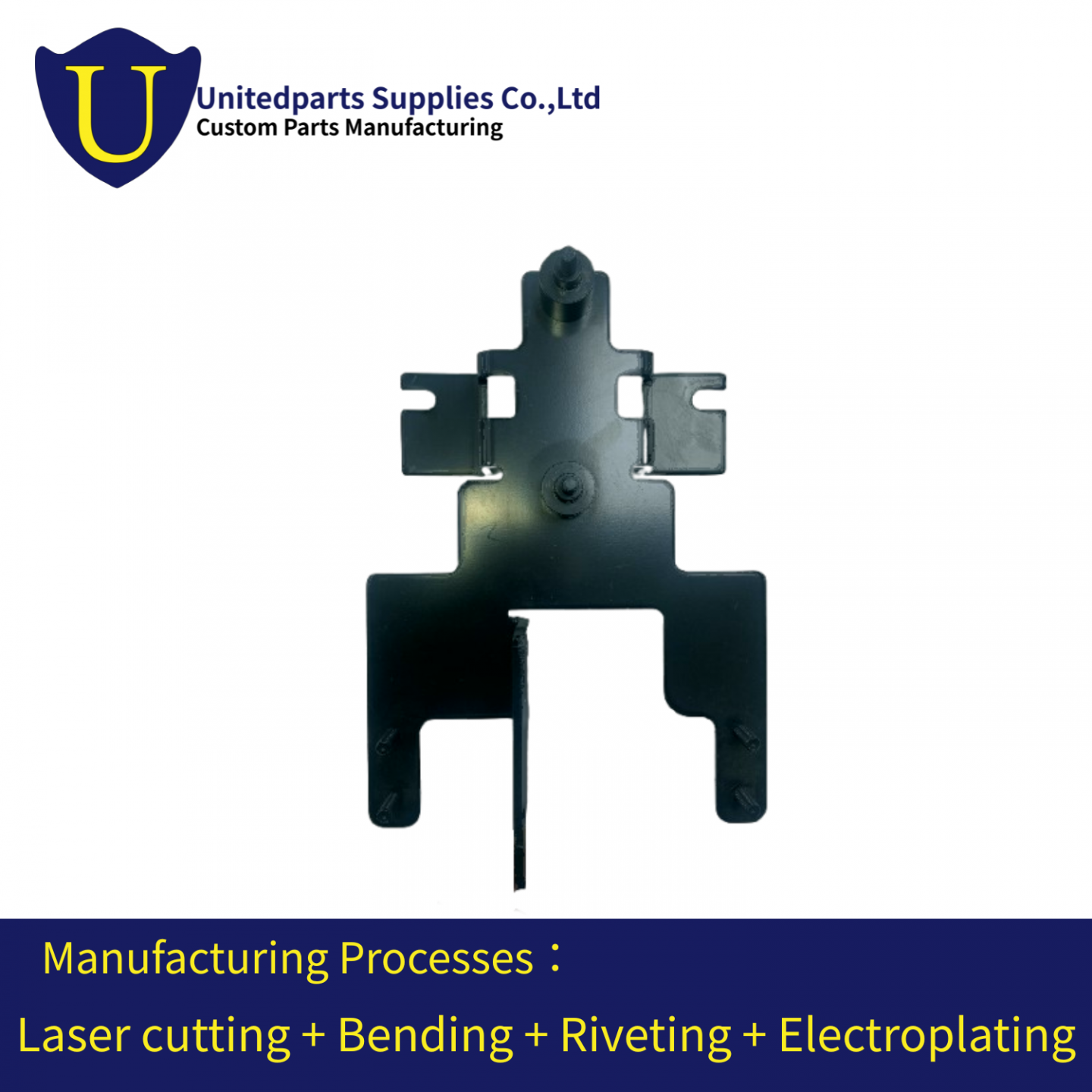

Metal stamping and laser cutting are widely used in the production of metal sheet components, enabling precise fabrication of parts with specific shapes and dimensional requirements.

These processes are often followed by secondary operations such as welding, clinching, tapping, and surface treatment to meet functional and assembly needs.

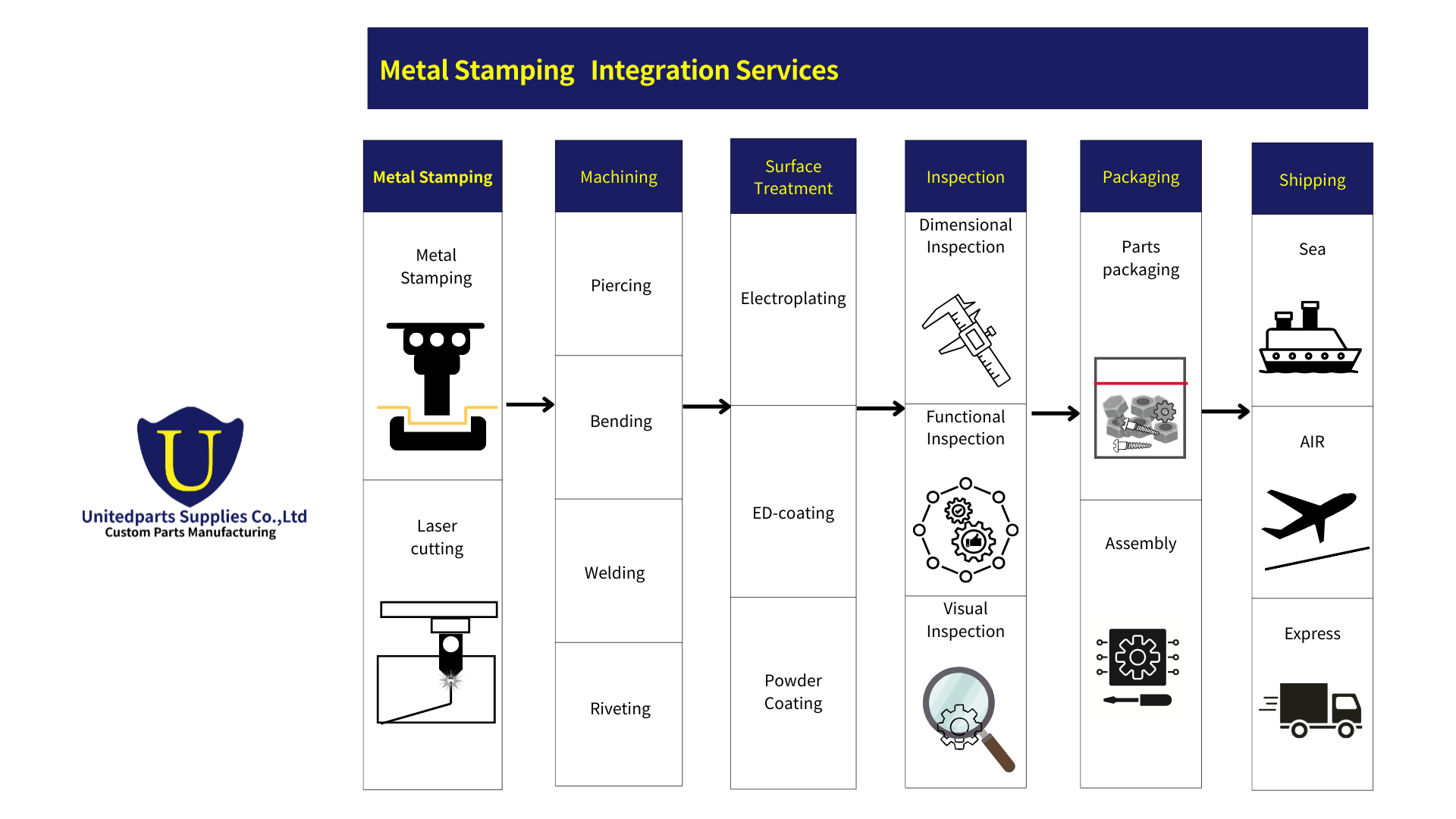

Unitedparts’Metal Stamping Integration Flow

From raw material preparation and secondary processing to surface treatment, inspection, packaging, and shipment, Unitedparts actively oversees and controls each stage of the sheet metal production process.

Through integrated process coordination and quality management, we ensure stable and consistent quality across every delivery, even in projects involving multiple downstream operations.

Unitedparts’Metal Stamping Integration Scope

Unitedparts’ typical service scope for sheet metal stamping and laser cutting.

|

|

Metal stamping | Laser cutting |

| Materials Typical |

Common metal sheets, including SPCC and SUS304 | Metal and non-metal materials, including SPCC and SUS304 |

| Applications |

|

Suitable for development projects, prototypes, and low-volume parts without the need for tooling |

| Secondary Operations | Welding, riveting, clinching (PEM fasteners), and tapping | Welding, riveting, clinching (PEM fasteners), and tapping |

United Processes, Parts with Consistent Quality

Sheet metal projects offer flexible process combinations. Simple parts may require only stamping or laser cutting with surface finishing, while more complex projects can involve welding, press-fit fastening, tapping, inspection, and final packaging.

With over twenty years of experience in process integration for overseas customers, Unitedparts applies project management at every stage to reduce coordination risks and maintain clear alignment across all processes. This approach ensures consistent quality and reliable delivery, regardless of project complexity.

Contact Unitedparts to manage your sheet metal projects with greater control and confidence.