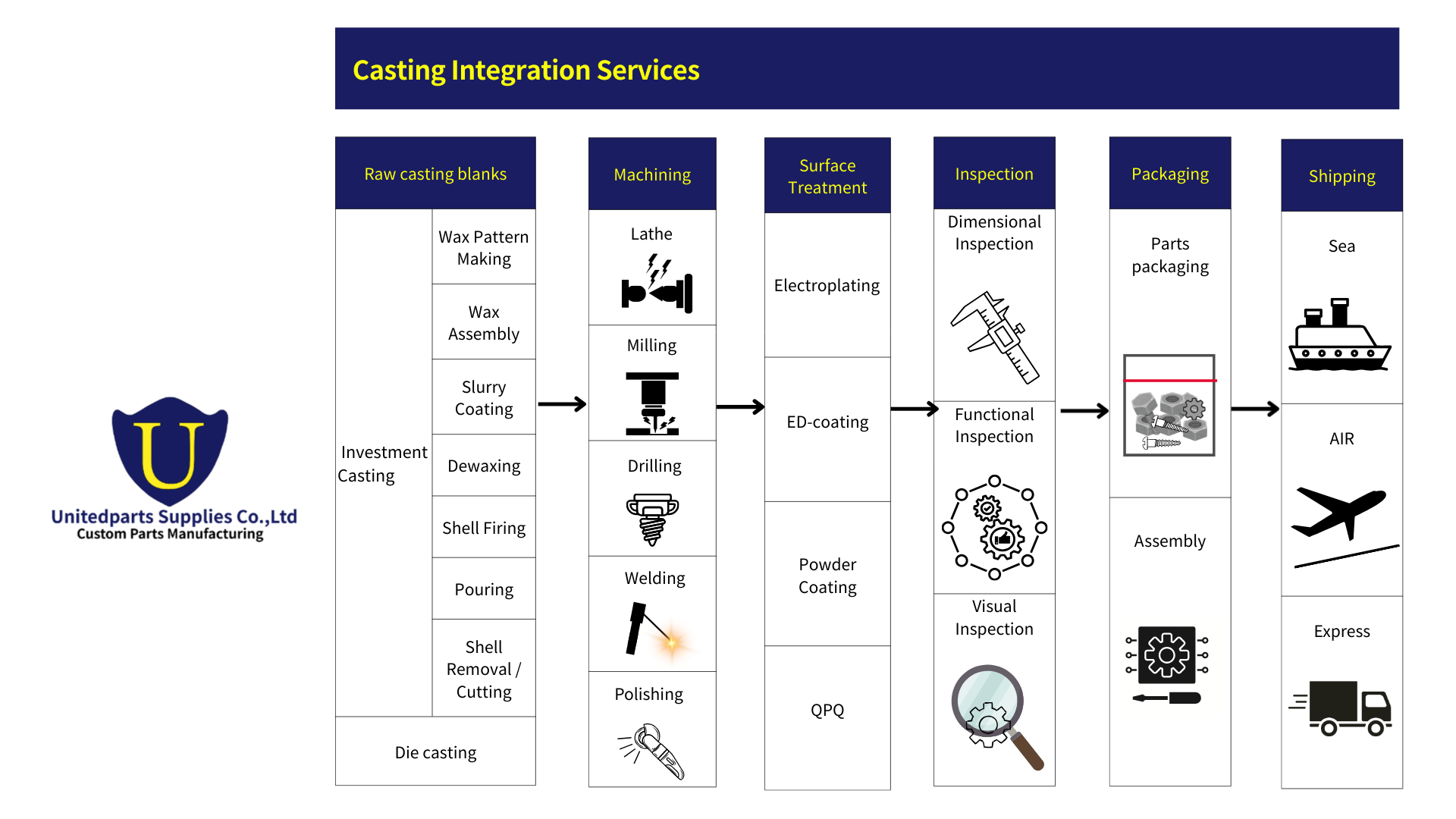

Unitedparts’Casting Integration Services

From raw casting blanks to finished, shipment-ready products, casting projects involve coordination across multiple processes and technical disciplines. From raw casting stages such as wax pattern making, pouring, and shell removal, through CNC machining and surface treatment, to final assembly, packaging, and shipment, each phase must be carefully aligned to ensure overall quality and consistency.

Unitedparts’Casting Integration Flow

While cross-process collaboration is essential to achieving a complete and functional end product, it also introduces risks related to information gaps and quality deviations.

Unitedparts actively manages these risks by engaging at every stage through close communication, quality monitoring, and progress tracking.

Through integrated project management, we ensure consistent process standards, stable quality outcomes, and reliable delivery from production to shipment.

Unitedparts’Casting Integration Scope

Unitedparts’ casting integration services primarily cover:

Investment Casting and Die Casting

|

|

Investment casting | Die casting |

| Materials Typical |

Suitable for a wide range of metals and alloys, such as: 4140 / 8620 / SUS304 | Aluminum, zinc, magnesium, and their alloys, such as: ADC10 / ADC12 / Zamak 3 |

| Applications |

|

|

左右滑動看表格

左右滑動看表格United Processes, Parts with Consistent Quality

The true value of casting projects lies not in individual processes, but in how effectively they are integrated and managed as a whole.

Unitedparts places project management at the center, overseeing each stage from casting and machining to final shipment. By preventing miscommunication between multiple processes, we ensure consistent quality and reliable delivery.

If your products involve multiple processes and strict quality requirements, contact Unitedparts to turn integrated execution into your competitive advantage.