Plastic injection molding is widely used across industries, from consumer goods to advanced mechanical and industrial engineering.

It offers the precision, consistency, and design flexibility needed for complex components in automation and machinery, while maintaining stable quality in high-volume production.

The following sections explore how the process works, its key features, and how it extends into diverse manufacturing applications.

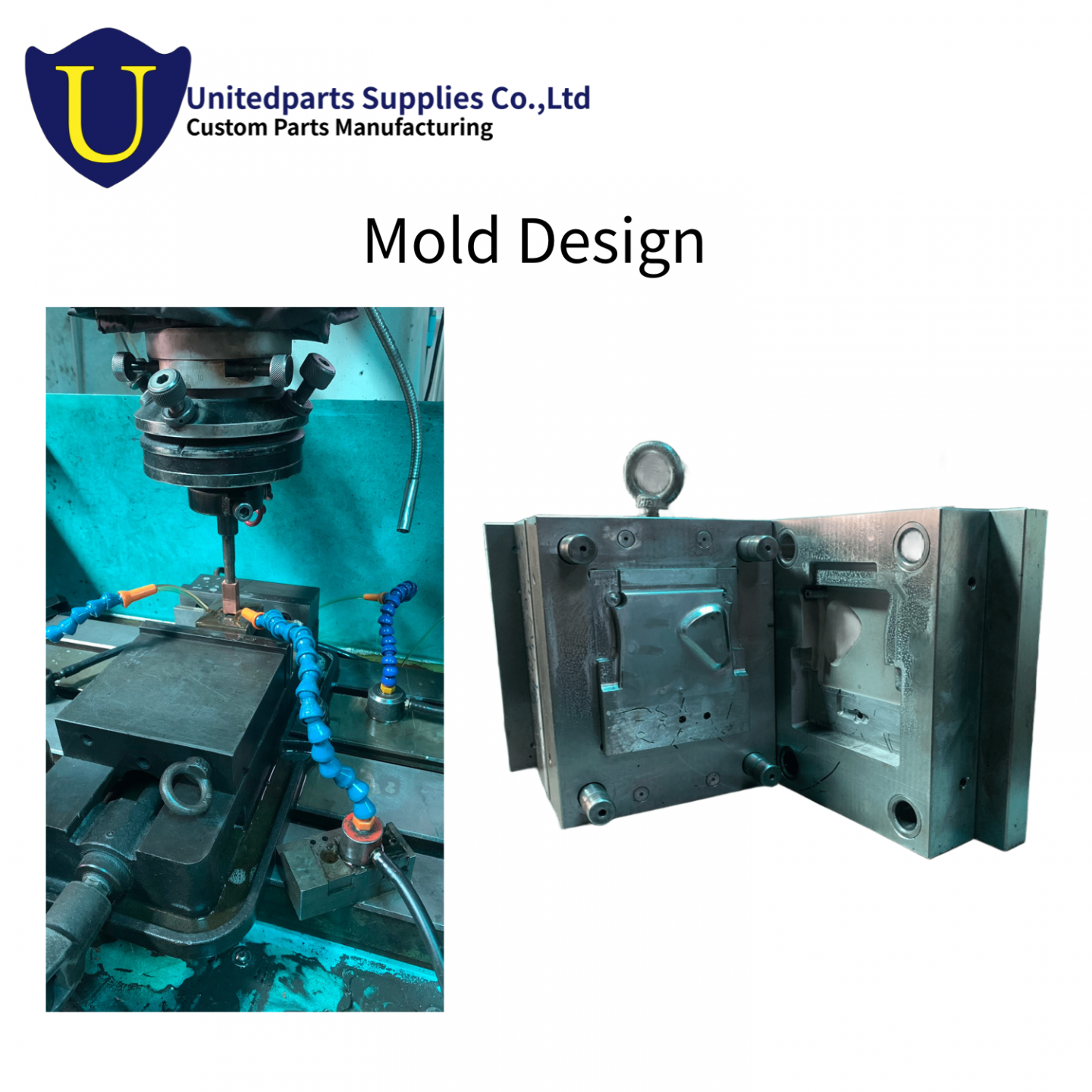

I. The Basic Principle of Plastic Injection Molding

Injection molding is a process that melts thermoplastic pellets and forces the molten material into a precision mold under high pressure. Once cooled and solidified, the part retains the exact geometry defined by the mold.

Injection molding follows a repeating cycle of key stages that define the process. Below are the main steps involved in forming a finished part.

1. Clamping and Material Preparation

The two halves of the mold—core and cavity—are securely clamped together under high pressure. Thermoplastic pellets are then loaded into the hopper of the injection molding machine, ready for processing.

2. Melting and Injection

The dried plastic material is fed into the heated barrel, where the rotating screw melts and mixes it into a viscous molten resin. The molten plastic is then injected into the mold cavity under controlled pressure.

3. Packing and Cooling

Once the mold is filled, pressure is maintained to prevent backflow, and plastic is continuously injected to compensate for material shrinkage. The cooling system solidifies the resin, ensuring dimensional stability and minimizing surface defects such as sink marks.

4. Mold Opening and Ejection

After the part has fully cooled and hardened, the mold opens. An ejection system pushes the molded part out of the cavity.

5. Finishing and Post-Processing

Any remaining sprues, runners, or flash are trimmed to achieve precise dimensions and a clean appearance. This completes the molding cycle and results in a high-precision, dimensionally consistent part.

In this process, the main controllable parameters are temperature, injection pressure, holding pressure, and cooling time, which define the part’s dimensional precision and surface finish.

-

Temperature – Proper temperature control keeps the material flowing evenly and prevents defects such as burn marks or short shots.

-

Pressure – The right injection and holding pressure ensure the cavity is fully packed and the part maintains uniform density.

-

Cooling Time – Balanced cooling avoids warping or shrinkage and helps maintain production efficiency.

II. Key Features and Advantages

-

High Production Efficiency: Ideal for mass production; parts can be molded within seconds.

-

Excellent Dimensional Consistency: Stable molding conditions ensure repeatable accuracy and uniform quality.

-

Capability for Complex Geometries: Enables the production of intricate and precise designs such as snap-fits, ribs, and undercuts.

-

Automated production: The process supports full automation, reducing manual intervention and improving production efficiency.

-

Integration with Other Processes: Compatible with insert molding, two-shot molding, and overmolding for added functionality.

-

Superior Surface Finish: Parts can be molded with smooth or textured surfaces, reducing post-processing.

-

High Material Utilization: Scrap or runner materials can be recycled, reducing waste and cost.

-

High Tooling and Equipment Investment: High-precision, durable molds and essential auxiliary systems demand significant upfront cost. However, injection molding becomes cost-efficient in large-volume production.

III. Extended Molding Techniques

Modern manufacturing demands have driven the evolution of several advanced injection molding methods:

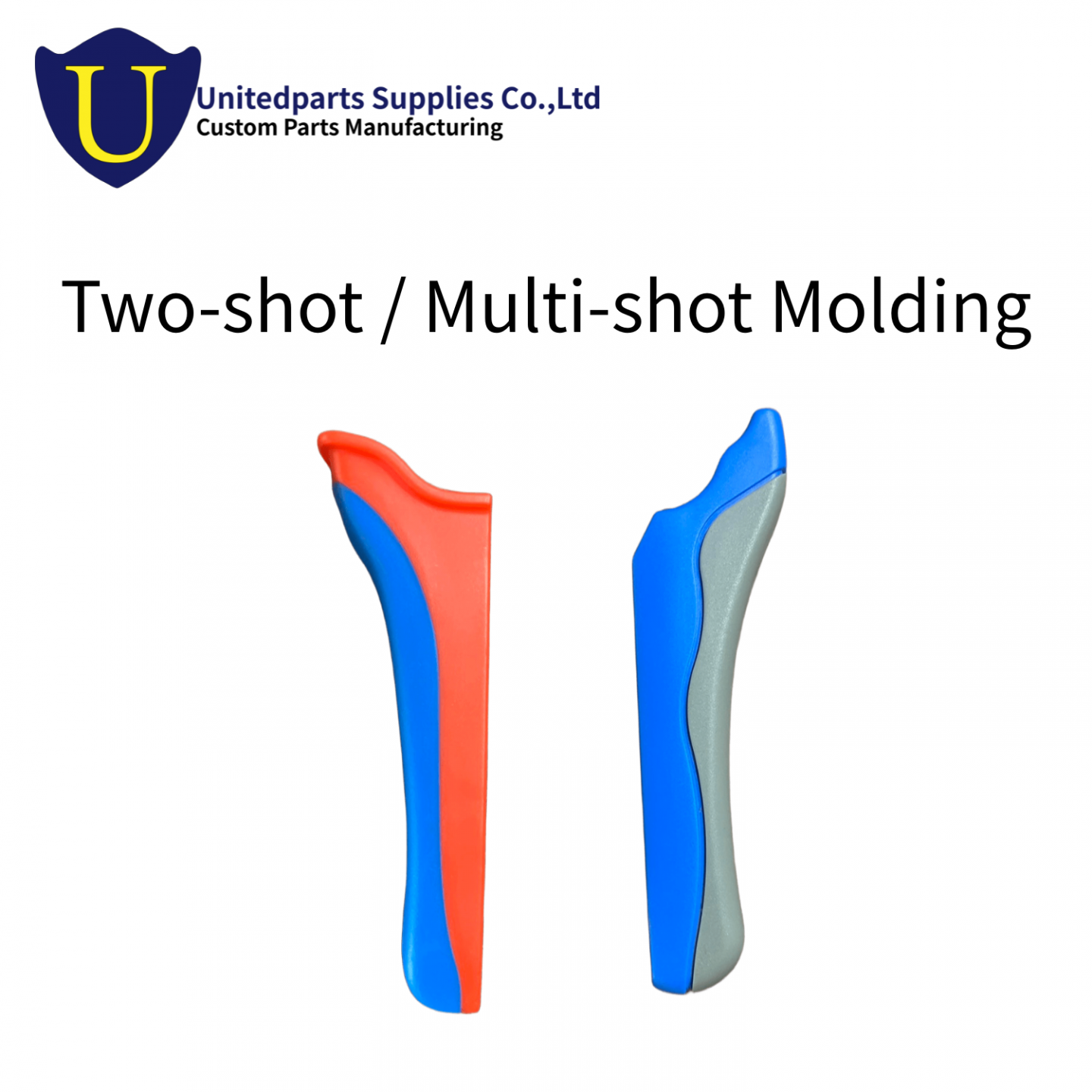

1. Two-shot Molding

Two different materials or colors are injected sequentially in the same mold to form a single, integrated part. Commonly used for appearance parts or products combining soft and hard materials, such as handles and buttons.

2. Insert Molding

Embeds metal or electronic parts into the mold before plastic injection, enhancing mechanical strength or electrical connectivity.

Frequently used in automotive and connector parts.

3. Overmolding

A second plastic material is molded directly over a preformed part to create a protective or non-slip surface, often used for tool grips and medical device housings.

These variations make injection molding suitable for everything from micro-precision components to multi-material assemblies.

IV. Common Applications

With its high production efficiency and design flexibility, plastic injection molding is used across diverse industries:

| Industry | Typical Products | Performance Requirements |

| Automotive | Dashboards, door handles, light covers, and interior panels | Heat resistance, impact-resistant, and dimensional stability |

| Electronics & Communications |

Casings, connectors, terminals, keypads |

Electrical insulation, accuracy |

| Medical Devices | Syringe parts, housings, and test tube racks | Cleanliness, precision |

| Home Appliances & Consumer Goods | Panels, buttons, containers, toys | Aesthetic surface, lightweight design |

| Automation & Industrial Equipment | Covers, brackets, functional components | High strength, assembly precision |

V. Conclusion

Plastic injection molding combines efficiency, precision, and automation, making it a core process in modern manufacturing. Extended methods such as two-shot, insert, and multi-material molding broaden its use across industries.

Share your drawings with Unitedparts for tailored evaluation and molding advice.