Casting is one of the most essential metal forming processes in modern manufacturing. By pouring molten metal into a mold to solidify, casting produces parts with complex geometries, stable structures, and reliable performance.

Depending on mold design, production requirements, and industrial applications, four main casting methods are commonly used: Sand Casting, Die Casting, Investment Casting, and Gravity Casting.

Each process has its own advantages and limitations, making it suitable for different types of parts and industries.

Sand Casting

Sand Casting forms molten metal into medium and large parts using molds made of sand. Due to the low cost and ease of modification of the molds, this method offers flexibility for prototyping and for designs that may evolve during development.

It is suitable for a variety of metals including iron, steel and aluminum alloys, and can accommodate heavy or oversized parts. Typical applications include machine bases, pump housings, structural brackets and agricultural equipment parts.

The surfaces are usually rougher and the dimensions less precise than with other casting methods, so additional machining is often required.

Die Casting

Die Casting injects molten metal into permanent steel molds under high pressure and speed. This process produces parts with smooth surfaces and consistent dimensions, making it well suited for medium to high volume production.

It is commonly used with non ferrous alloys such as aluminum and zinc, which enable lightweight designs with uniform wall thickness. While die casting offers high efficiency and precision, it also involves higher mold development costs.

In addition, castings may contain porosity that can limit heat treatment or use in high temperature conditions. Typical applications include electronic housings, Automotive parts and 3C components.

Unitedparts provides die casting and assembly services in aluminum and zinc alloys, supporting applications in aerospace parts, electronic housings and medical components.

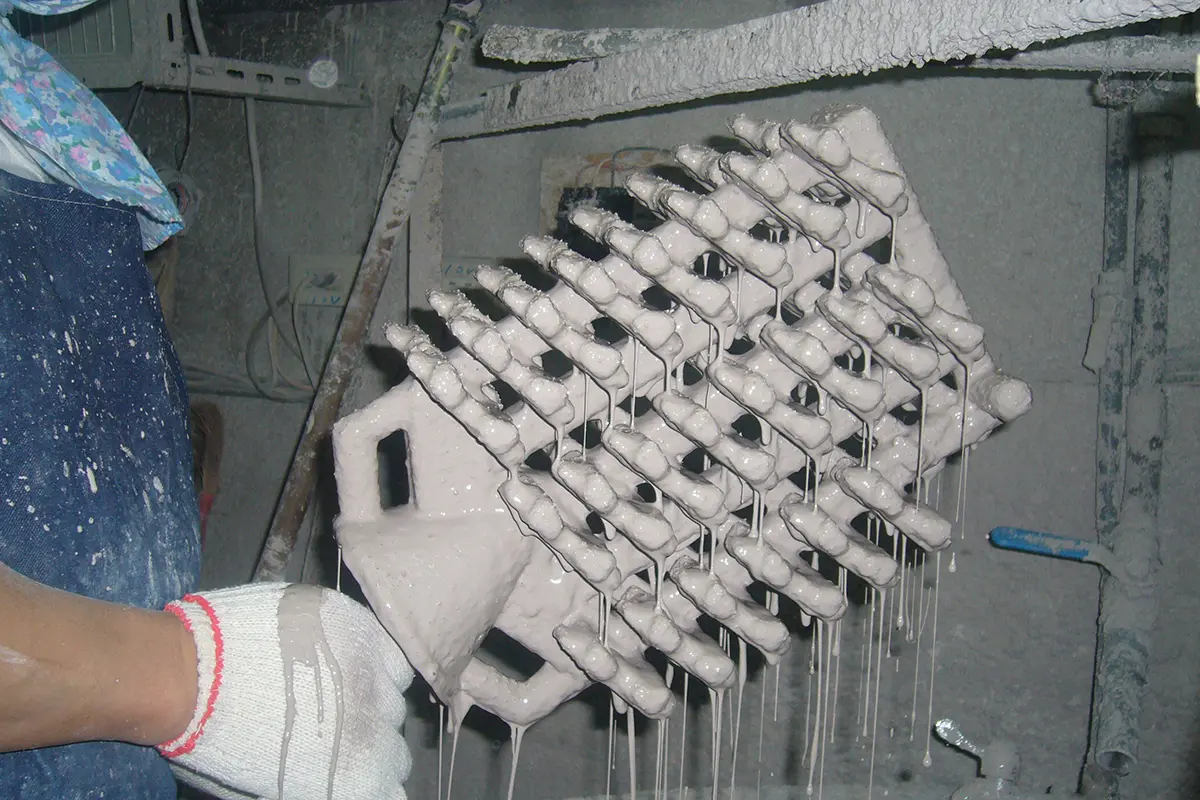

Investment Casting (Lost-wax casting)

Investment Casting, also known as Lost-Wax Casting, produces highly precise parts with complex geometries by using wax patterns coated in ceramic shells. This process is particularly valuable for creating shapes with undercuts or enclosed cavities that cannot be released from conventional molds, giving it an advantage over other casting methods.

It delivers excellent dimensional stability and fine surface quality, and works with materials such as stainless steel, alloy steel and other high strength metals.

While the production cycle is longer and the cost higher than other casting processes, it is ideal for applications such as medical instruments, automotive parts and automatic door components.

Unitedparts delivers over 500,000 precision investment casting parts each year, supported by integrated CNC machining and finishing services.

Gravity Casting

Gravity Casting relies on the natural flow of molten metal into a permanent mold, where it solidifies under gravity alone. The process produces parts with dense structures and stable mechanical strength, making it suitable for medium volume production.

It works particularly well with aluminum alloys, delivering reliable performance for components that require durability and dimensional stability. Because the filling speed is slower and there is no applied pressure, the process is best suited for parts with simpler geometries rather than extremely thin or intricate designs.

Typical applications include automotive housings, valve covers, heat sinks and industrial equipment parts.

Casting Methods Comparison

| Casting Method | Mold Type | Suitable Volume | Precision / Surface |

Geometric Complexity |

Material Range | Typical Applications |

Provided by Unitedparts |

| Sand Casting | Sand mold (disposable) | Low to Medium | Moderate / Rough | Moderate | Iron, Steel, Aluminum alloys | Machine bases, pump housings, agricultural parts | ✘ |

| Die Casting | Steel mold (permanent) | Medium to High | High / Smooth | Medium (needs draft) | Aluminum, Zinc alloys | Electronic housings, automotive parts, aerospace parts | ✔ |

| Investment Casting | Steel mold (permanent) | Low to Medium | Very High / Fine | High (allows undercuts) | Carbon steel, stainless steel, cast iron | Medical instruments, automotive parts, door components | ✔ |

| Gravity Casting | Steel mold (permanent) | Medium | Medium / Smooth | Simple to Moderate | Aluminum alloys | Automotive housings, valve covers, industrial parts | ✘ |

Conclusion

Each casting method has its own conditions and advantages. Selecting the right process depends on part geometry, material, production volume, and post machining process.

Unitedparts welcomes your drawings to explore casting solutions together.