This article introduces the fundamentals of metal stamping—its principles, processes, and applications.

I. Principles and Characteristics of Metal Stamping

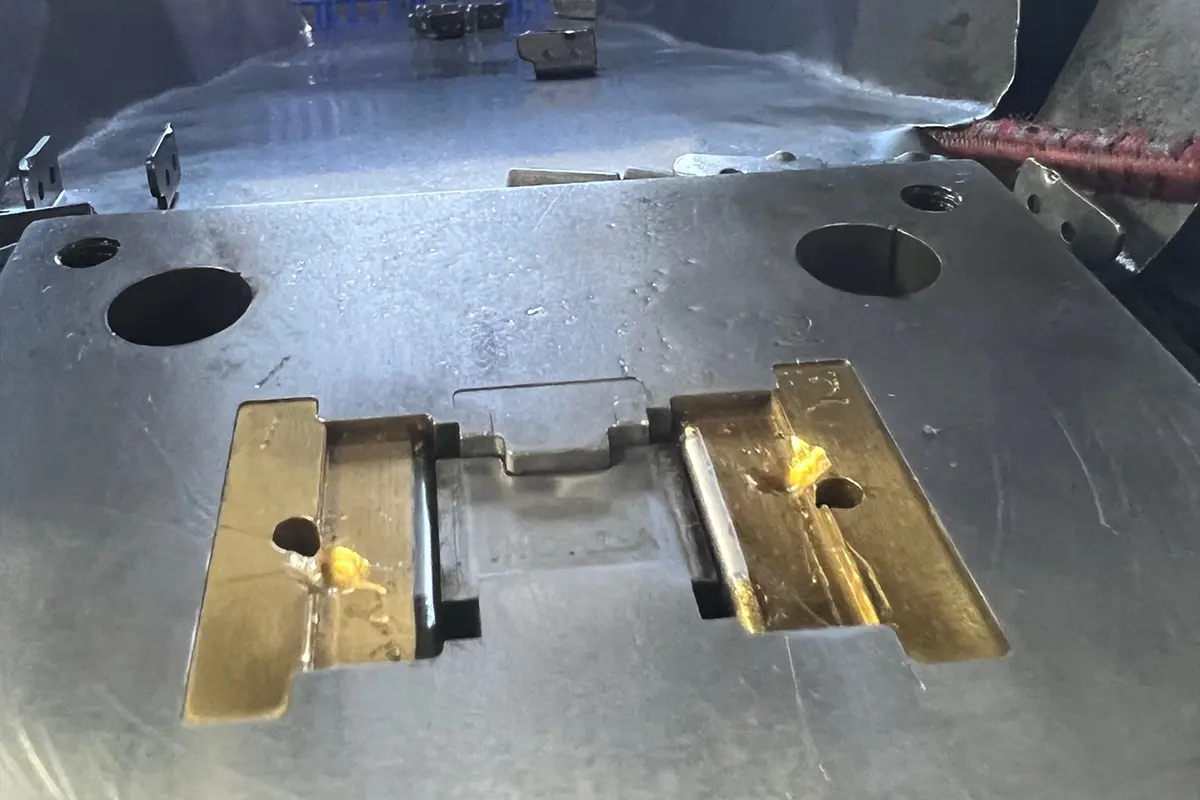

Metal stamping is a cold-forming method that shapes sheet metal into precise parts without heating. Using presses and dies, it performs punching, bending, shearing and deep drawing with high precision and consistent quality. These strengths make it a dependable process for medium to high volume manufacturing.

Since metal stamping does not involve heat treatment, the material retains its original mechanical properties. This makes it a reliable choice for parts that must handle stress or maintain precision and stability, such as automotive components, electronic housings, industrial machinery, and precision hardware.

Optimizing the stamping layout maximizes material utilization and minimizes waste, ensuring efficient and cost-effective production.

The process is commonly applied to 0.2–5.0 mm sheet metals, using ductile materials such as stainless steel, aluminum, carbon steel, and copper alloys to reduce risks like cracking or springback and ensure stable quality.

II. Common Stamping Processes and Uses

Different stamping methods serve distinct forming needs and applications. Below are four of the most widely used processes:

1. Piercing

Creates holes in sheet metal for locking points, ventilation, or assembly positions.

Applications:

Mounting screws, wires, and connectors in components such as electronic housings, panels, and brackets.

2. Shearing / Blanking

Cuts sheet metal along a defined outline to produce blanks or part contours.

Applications:

Sheet cutting, part contouring, or blanks prepared for further forming, such as control panels and decorative faceplates.

3. Bending

Forms sheet metal into specific angles, such as L- or U-shaped profiles.

Applications:

arts requiring strength and assembly angles, such as support frames, mounting plates, and interior fittings.

4. Deep Drawing

Transforms flat sheet metal into seamless cup or box shaped forms.

Applications:

Parts that require sealing and strength, such as metal housings, containers, lampshades, and automotive structures.

III. Application Fields of Metal Stamping

With fast processing speed and high product consistency, metal stamping is widely applied across multiple industries:

- Automation equipment and industrial hardware: mounting bases, bent components, installation plates, distribution panels

- Automotive and motorcycle parts: door hinges, structural brackets, pedal back plates, clips, protective covers

- Electronics: connector terminals, heat sinks, housing components

- Home appliances and architectural fittings: panels, button plates, door frame parts, decorative covers

As demand grows for lighter designs and stronger structures, stamping is often combined with processes such as welding, riveting, and coating to enhance value and widen applications.

Conclusion

Metal stamping delivers high forming efficiency, dimensional consistency, and effective material utilization, making it a key process for mass production of parts across industries.

Unitedparts can review your designs and recommend stamping processes suited to your requirements.