From blanks to fully functional precision parts, multiple machining steps are required to achieve the design requirements.

The main machining methods are CNC (Computer Numerical Control) and Traditional machining. Each has its strengths:

CNC machining relies on computer programming, ideal for complex geometries and parts requiring high consistency.

Traditional machining depends on skilled operators and flexible adjustments. It is suitable for specific requirements and small-batch production.

Unitedparts integrates both methods, offering a full range of machining services, including Lathe machining, Milling, Drilling, Welding, Grinding, Polishing, and Straightening.

Lathe Machining

Principle:

The workpiece is clamped and rotated while the cutting tool feeds along the axial or radial direction to perform turning operations on the outer diameter, inner holes, end faces, and threads.

Applications:

Commonly used for cylindrical and shaft-type parts such as shafts, sleeves, nuts, rotating components, and other round structures.

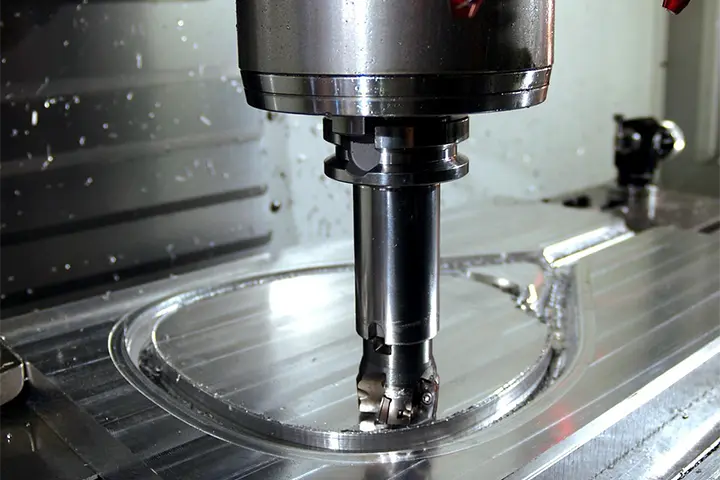

Milling Machining

Principle:

The rotating cutting tool removes material from flat surfaces, grooves, holes, or irregular contours while the workpiece is fixed or moved.

Applications:

Suitable for square shapes, complex geometries, and structural surfaces such as brackets, housings, guide rails, and connector plates.

Drilling

Principle:

The drill bit rotates and feeds axially to create holes, followed by tapping, countersinking, or other secondary processes as required.

Applications:

Widely used for screw holes, positioning holes, and through-holes, commonly seen in assembly structures and connector designs.

Welding

Principle:

Welding is a process that joins metal surfaces through the application of heat, pressure, or filler material to achieve permanent fusion.

Applications:

Suitable for assembling structural parts such as brackets, frames, and casings that require strength and integrity.

Straightening

Principle:

Mechanical correction restores parts deformed during machining or heat treatment to within specified tolerances.

Applications:

Commonly applied to long or flat workpieces such as shafts, steel bars, and stamped parts for dimensional accuracy.

Grinding / Polishing

Principle:

Abrasive tools such as grinding wheels, belts, or polishing media improve dimensional accuracy and surface finish while removing burrs.

Applications:

Used for precision surfaces or decorative finishing, commonly applied to housings and sealing faces.

| Machining Method | Applications |

| Lathe Machining | Best for cylindrical parts or outer diameter finishing, ensuring concentricity. |

| Milling Machining | Machining flat surfaces, slots, holes, and complex geometries. |

| Drilling | Pre-drilling for screw holes, assembly holes. |

| Welding | Joining parts into a single structure. |

| Straightening | 1. Correction of long bars or plate-shaped parts. 2. Adjustment of deformed workpieces. |

| Grinding / Polishing | 1. Enhancing surface finish and refinement. 2. Burr removal. |