Metal stamping and laser cutting are widely used in metal sheets.

Both processes handle thin sheets with precision, ensuring consistent geometry and smooth edges.

The process is usually completed with bending, welding, riveting, screw fastening, and surface treatments.

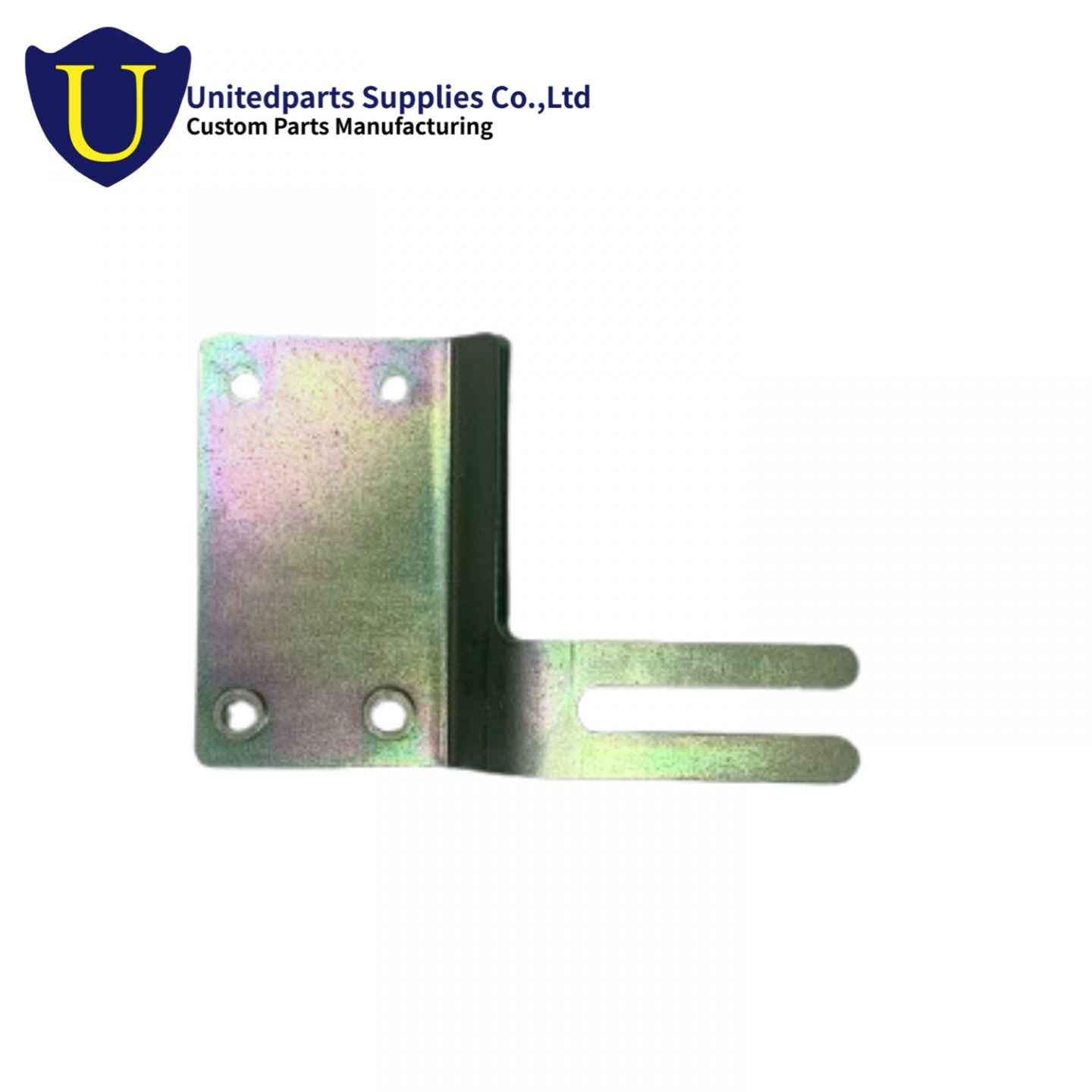

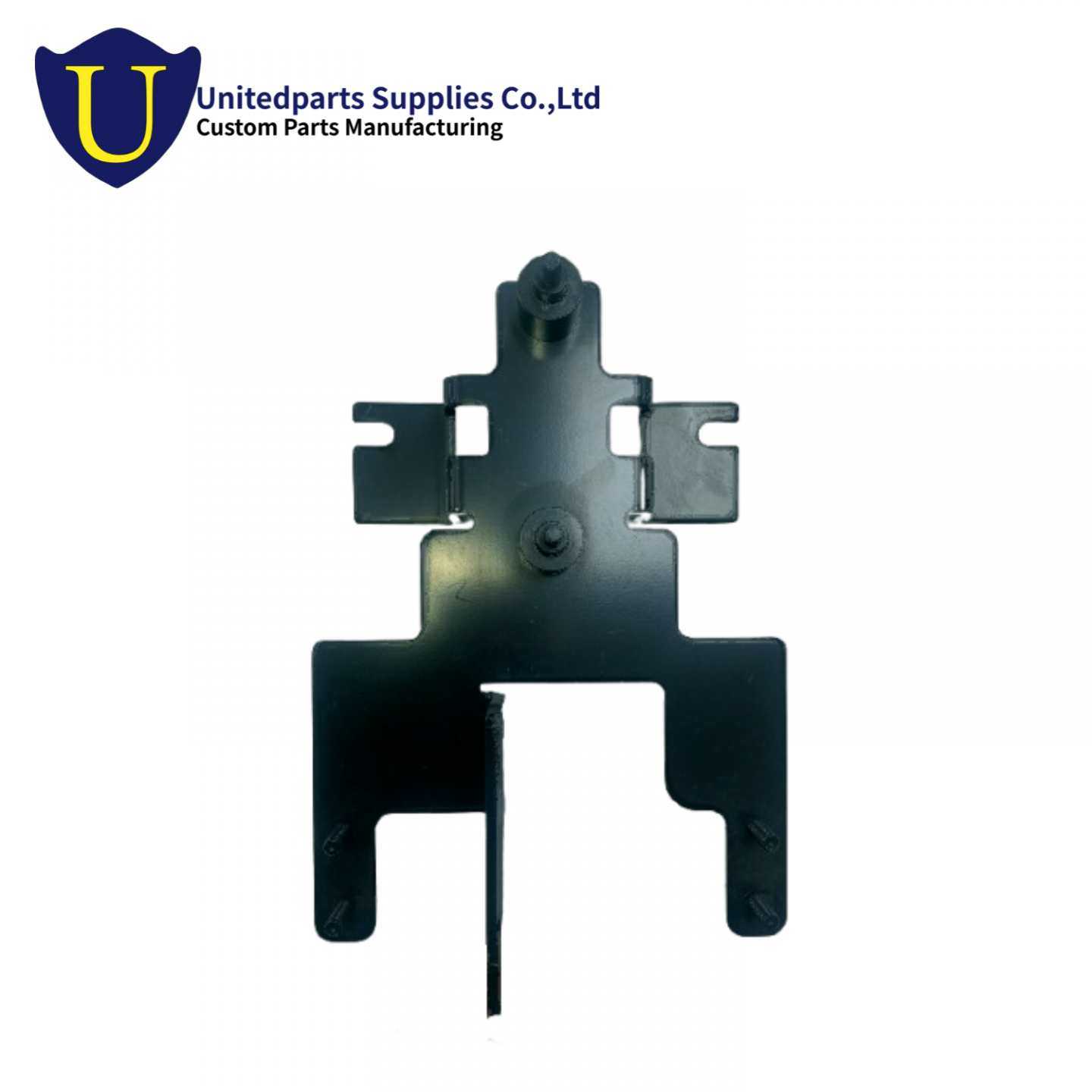

Metal Stamping

-

Features:

1. Metal stamping produces high-precision parts with stable dimensions and cost efficiency, enabled by tooling for mass production.

2. With tooling, piercing and bending are completed directly, reducing additional machining and improving cost efficiency.

3. Metal stamping parts can be joined by welding, riveting, screw fastening, or fasteners. -

Commonly used materials: 4140, 8620, SUS304.

-

Unitedparts provides welding, riveting, PEM nut installation, and screw fastening.

-

Applications:

Automatic door parts, automotive parts, and agricultural machinery parts.

Laser Cutting

-

Features:

1. Cuts with laser beams without the need for tooling.

2. Supports any shape or perforation with smooth edges, with no secondary finishing required.

3. Ideal for small-batch production and widely adopted in product development stages.

4. Applicable to a wide range of materials, whether metal or non-metal. -

Commonly used materials: SPCC/SUS304.

-

Unitedparts provides bending, welding, riveting, PEM nut installation, and screw fastening.

|

|

Metal Stamping | Laser Cutting |

| Features | 1. Produces high-precision parts with stable dimensions and cost efficiency, with piercing and bending completed directly through tooling to reduce additional machining. 2. Suitable for sheet thickness under 6 mm. |

1. Supports small-batch production without tooling. 2. Cuts 0.5~20 mm sheets into any shape or hole with smooth edges, no secondary finishing required. |

| Materials | Applicable to most sheet metals. | Wide range of materials, including metals and non-metals. |

| Efficiency | Mass production with tooling, suitable for high-volume runs. | Suited for small-batch production and rapid product development. |

| Applications | Widely applied to automotive housings, electronic components, and appliance enclosures. |

Applicable to various fields for development and sample parts. |